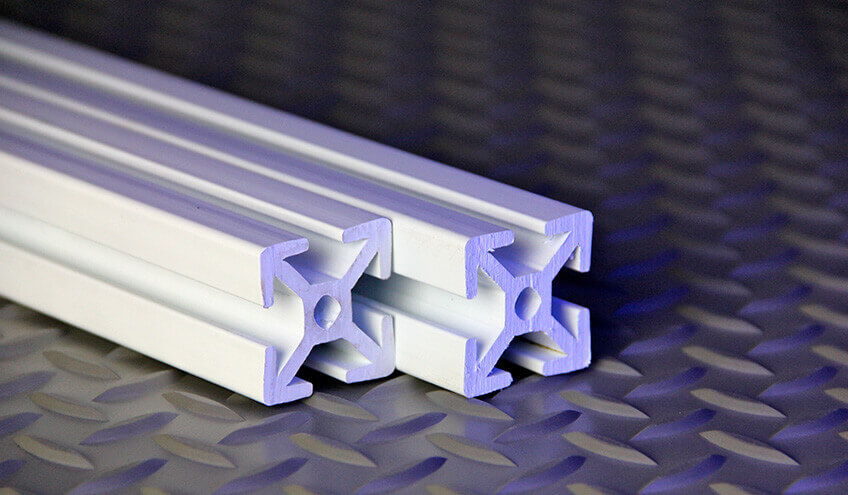

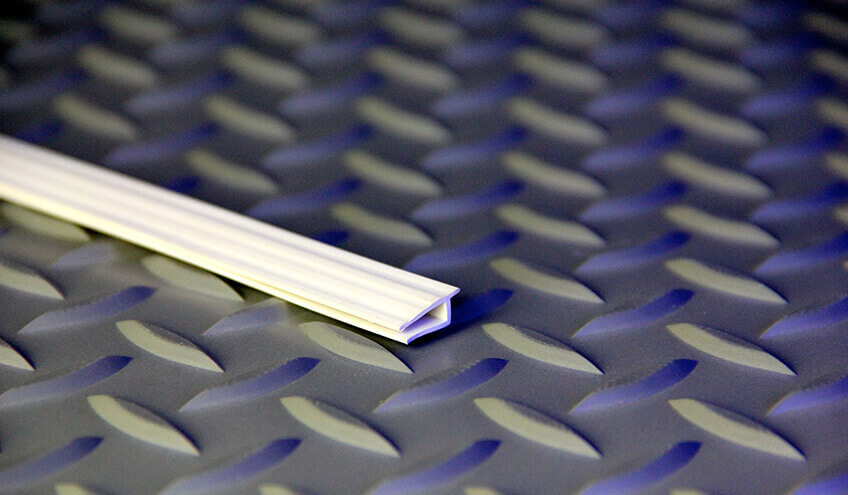

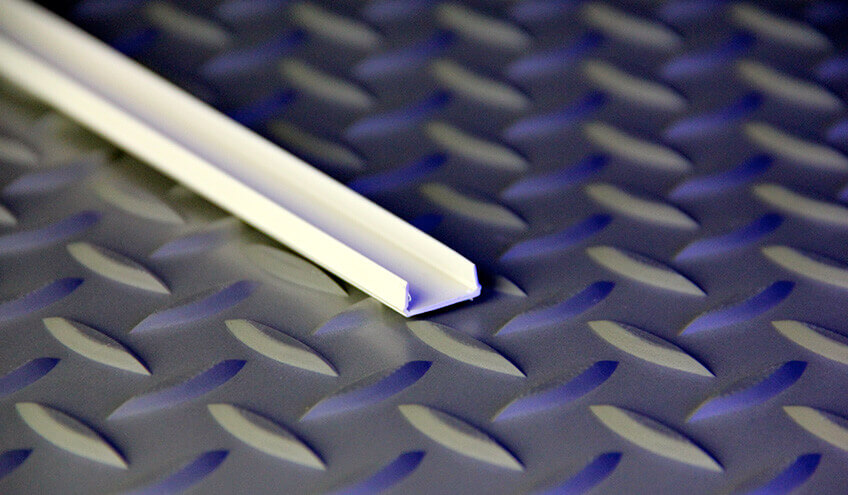

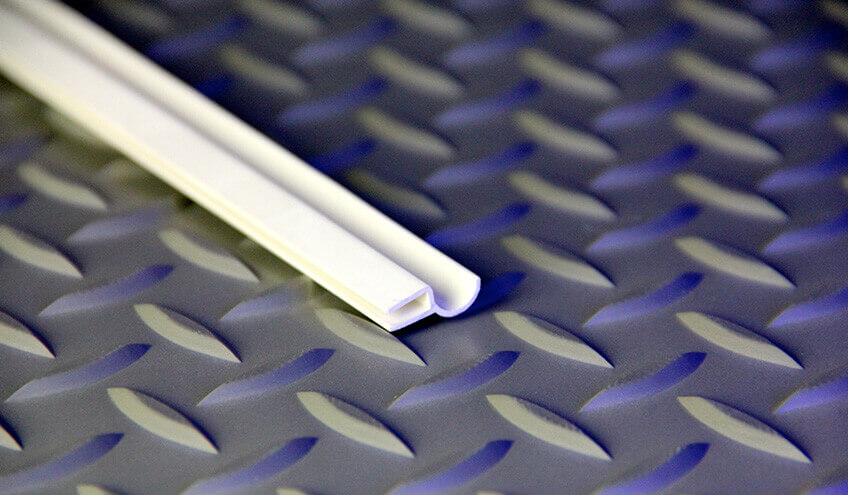

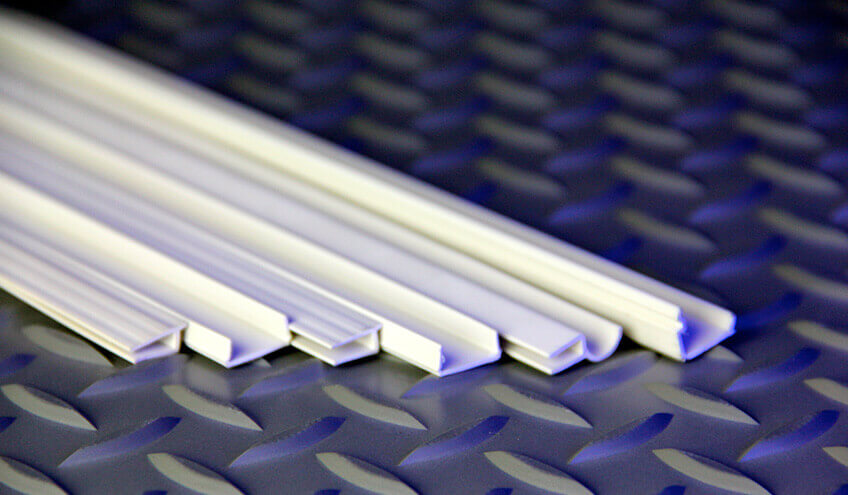

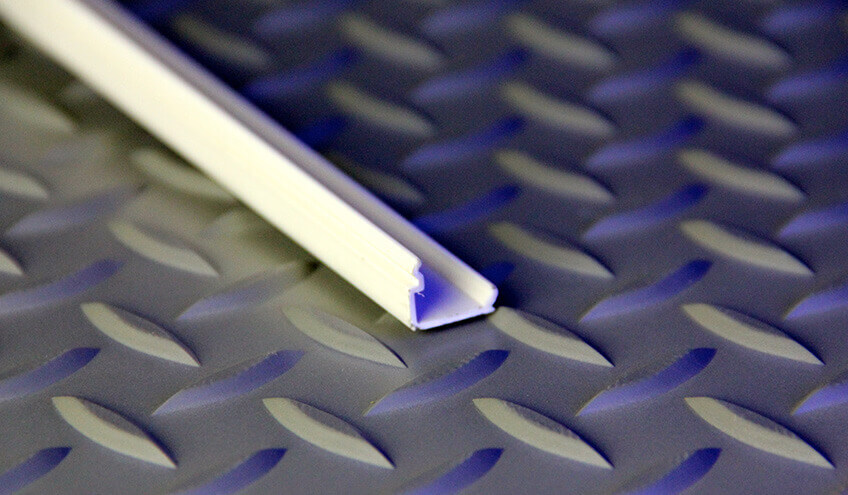

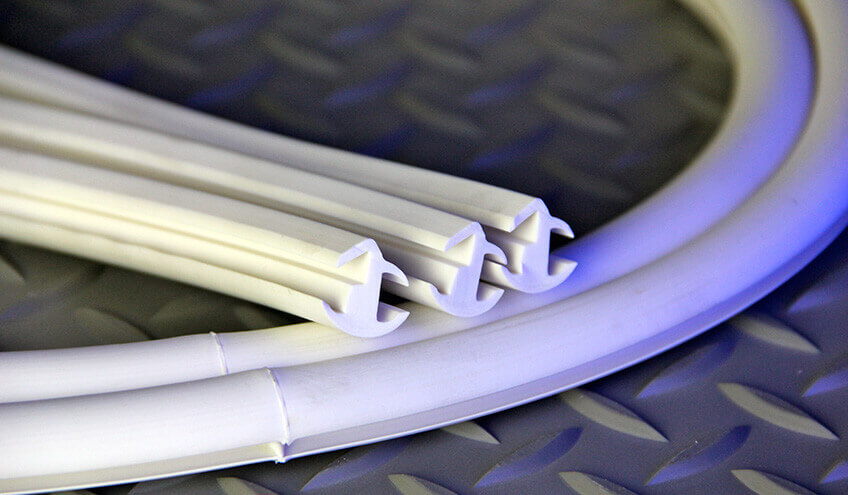

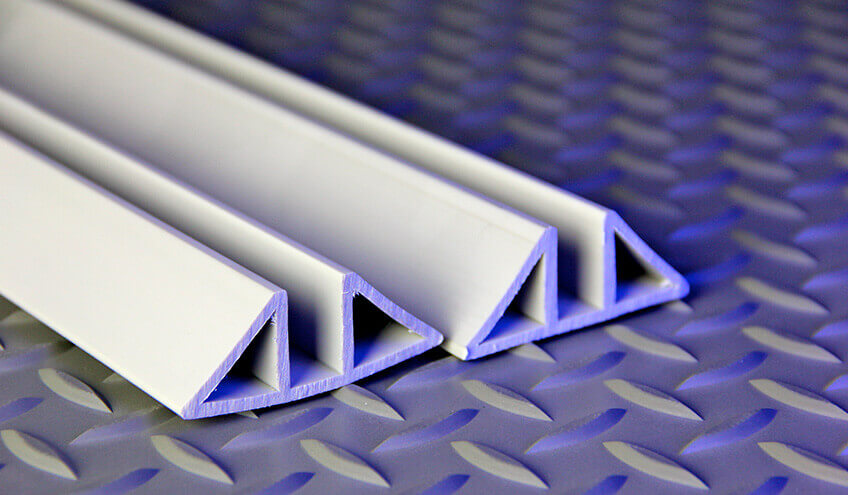

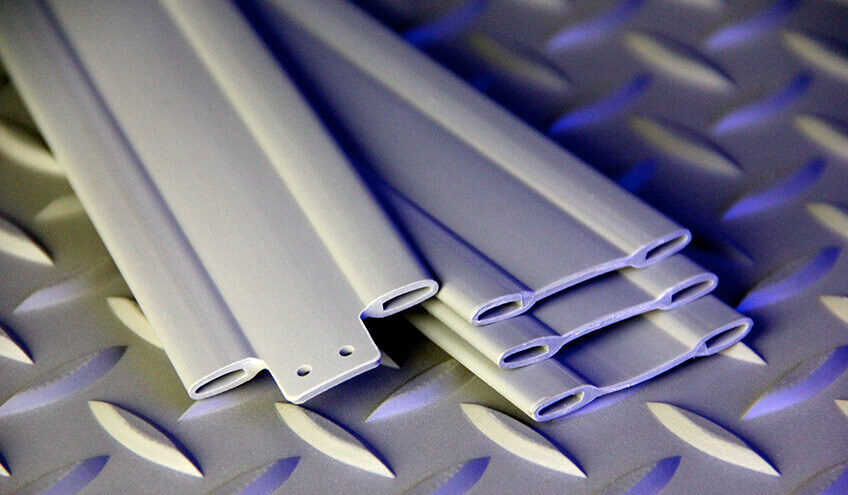

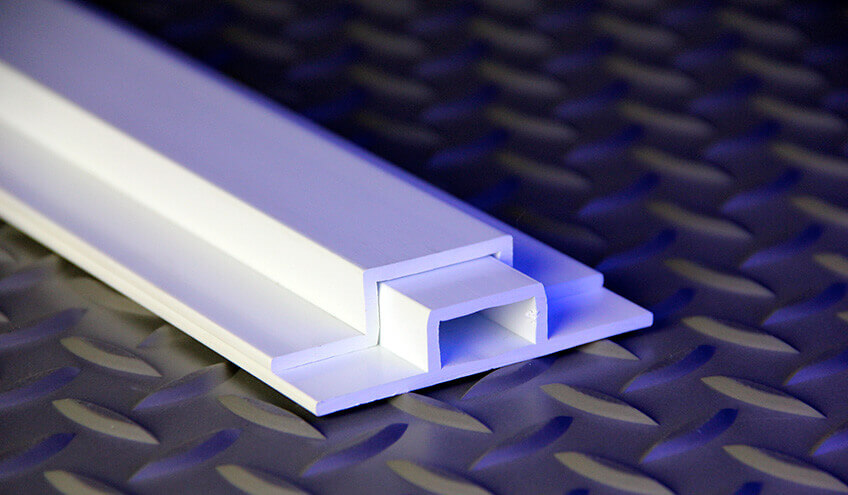

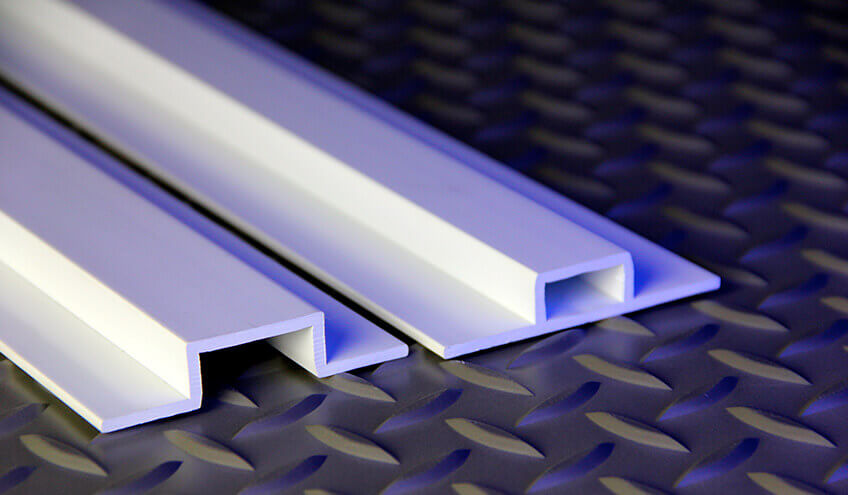

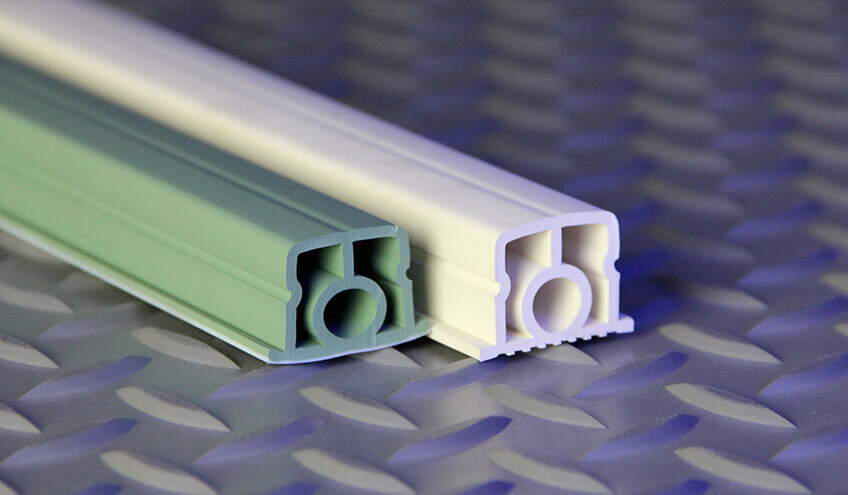

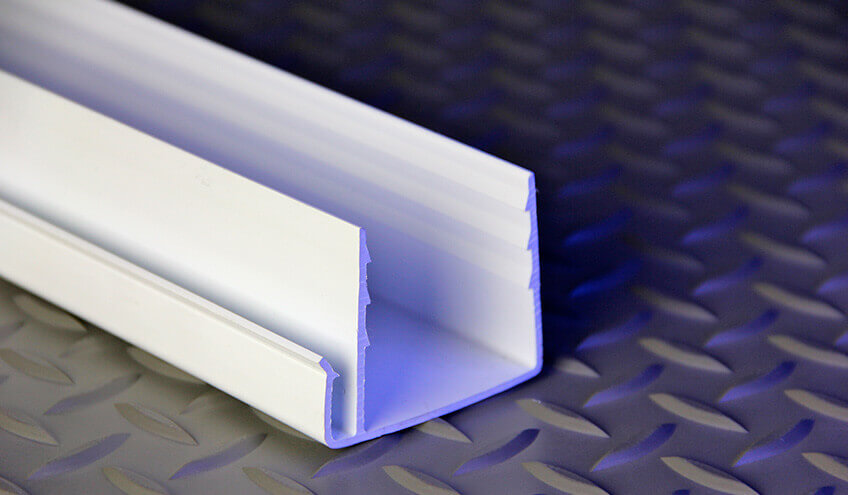

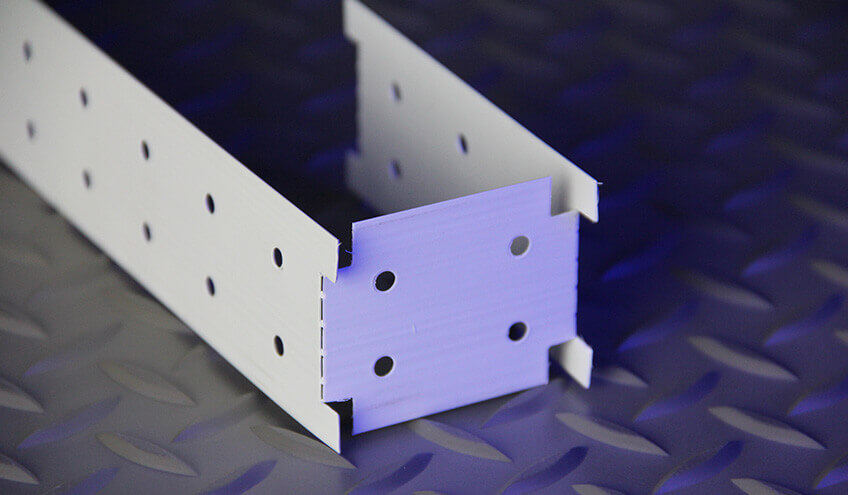

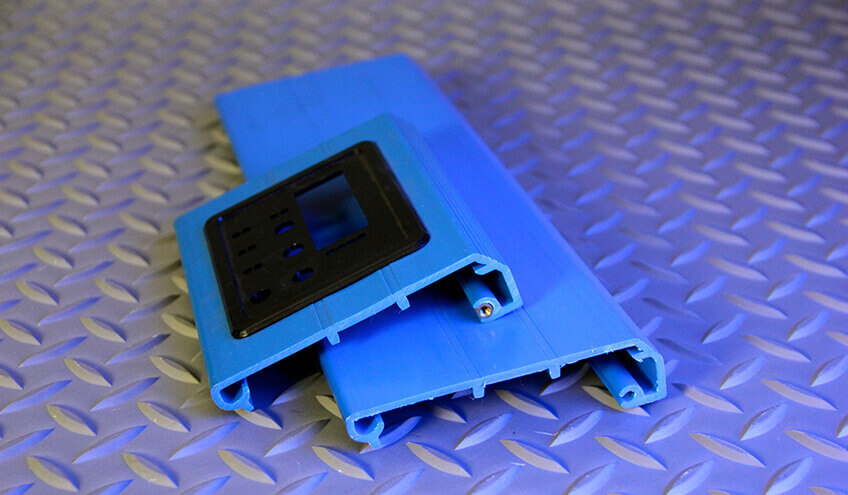

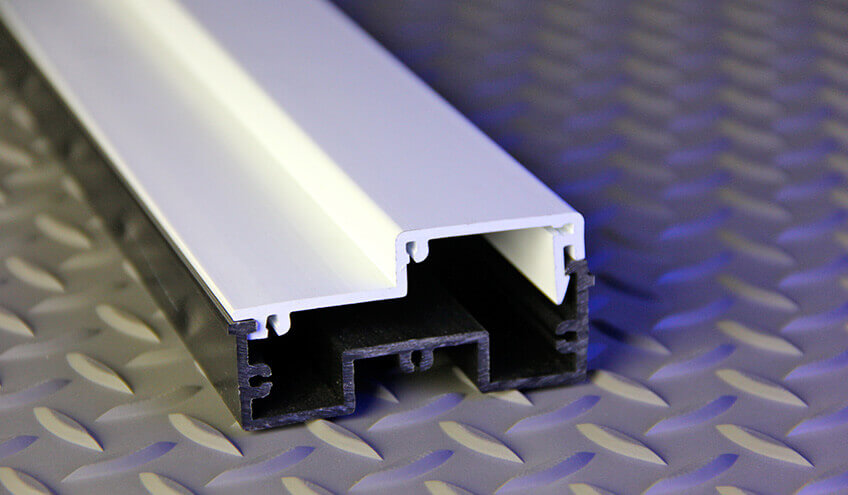

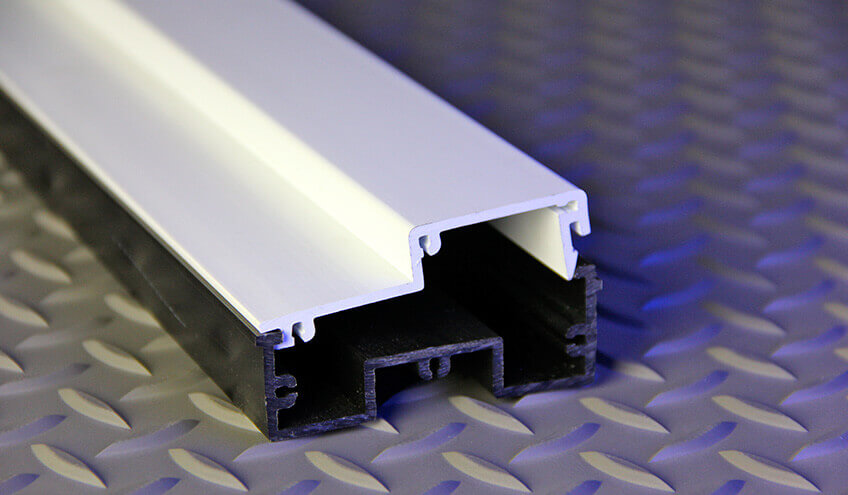

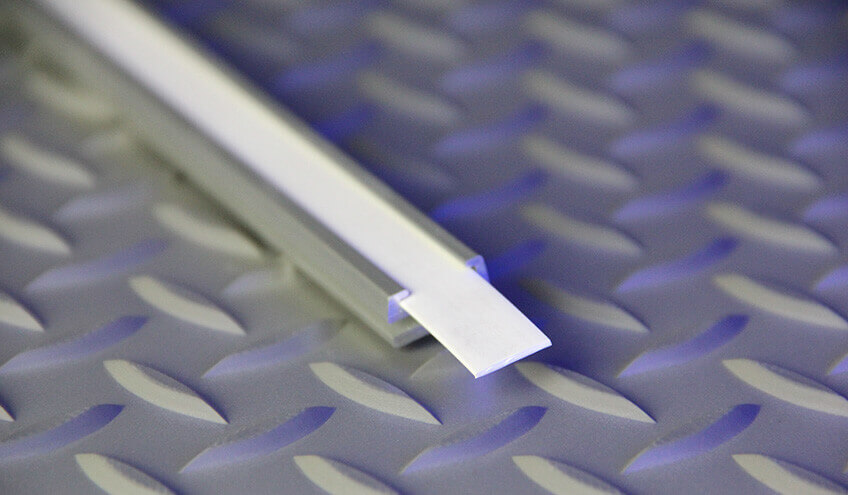

Custom plastic extrusions from Thermoprene are located in the “Polymer Valley”. Thermoprene has the capabilities to meet any plastic extrusion requirement. Thermopene thrives on the tough extruded plastic applications that push the manufacturing envelope. From standard tubing to highly intricate and multi-hollow shapes, you can rely on our depth of experience to assure that quality parts will be delivered on time and at the right price. Whatever your plastic extrusion application, Thermoprene can help.

Plastic Extrusions Capabilities

Thermoprene has the following capabilities:

- Plastic Extrusion & Molding

- Plastic Sheet Extrusions

- Custom Solid, Hollow & Multiple Hollow Shapes

- Dual Durometer

- Vacuum Calibration

- Adhesive Application (in line & secondary)

- Fabrication & Secondary

- Rigid, Flexible & Elastomeric Compounds

- Color Matching & Special Effect Additives.

- Custom Protective & Retail Packaging

Materials

Thermoprene has the extensive experience with the following plastic materials:

- ABS

- PVC

- HDPE & UHMW Polyethylene

- Polypropylene

- Polyurethane

- Polystyrene

- Nylon

- PETG

- TPR/TPE/TPV

- Acrylic

- PTFE

- Polycarbonate

Talk to one of our Experts

Since 1997, Thermoprene has specialized in the custom manufacture and supply of plastic extrusions, rubber extrusions and aluminum extrusions. We have the capabilities and expertise to competitively meet your most challenging polymer & aluminum forming requirements.

Designing Extruded Products

Transforming even the best ideas into functional products takes many special talents. At Thermoprene, we have the experience and resources to properly evaluate your requirements for the development of polymer and aluminum products.

Custom Services

Profile Extrusion, Extruded and Calendared Sheet, Molding

Secondary Fabrication, and Finishing Stock.

Plastic Extrusion Form

Ideas Formed

Get a quote for your plastic extrusion project